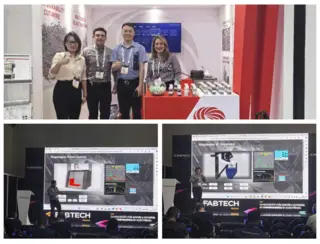

JX ABRASIVES Collaborates with Century-old PANGBORN, Showcases Turbine Technology and Multi-brand Parts Supply

Recently, technical experts from the renowned century-old American shot blasting equipment manufacturer, PANGBORN, had the privilege to demonstrate and elucidate the latest turbine technology for the JX ABRASIVES team. This technical demonstration not only provided JX BLAST with valuable learning opportunities but also strengthened their partnership with PANGBORN. As an enterprise committed to continuous learning and improvement, JX ABRASIVES has been dedicated to providing high-quality...