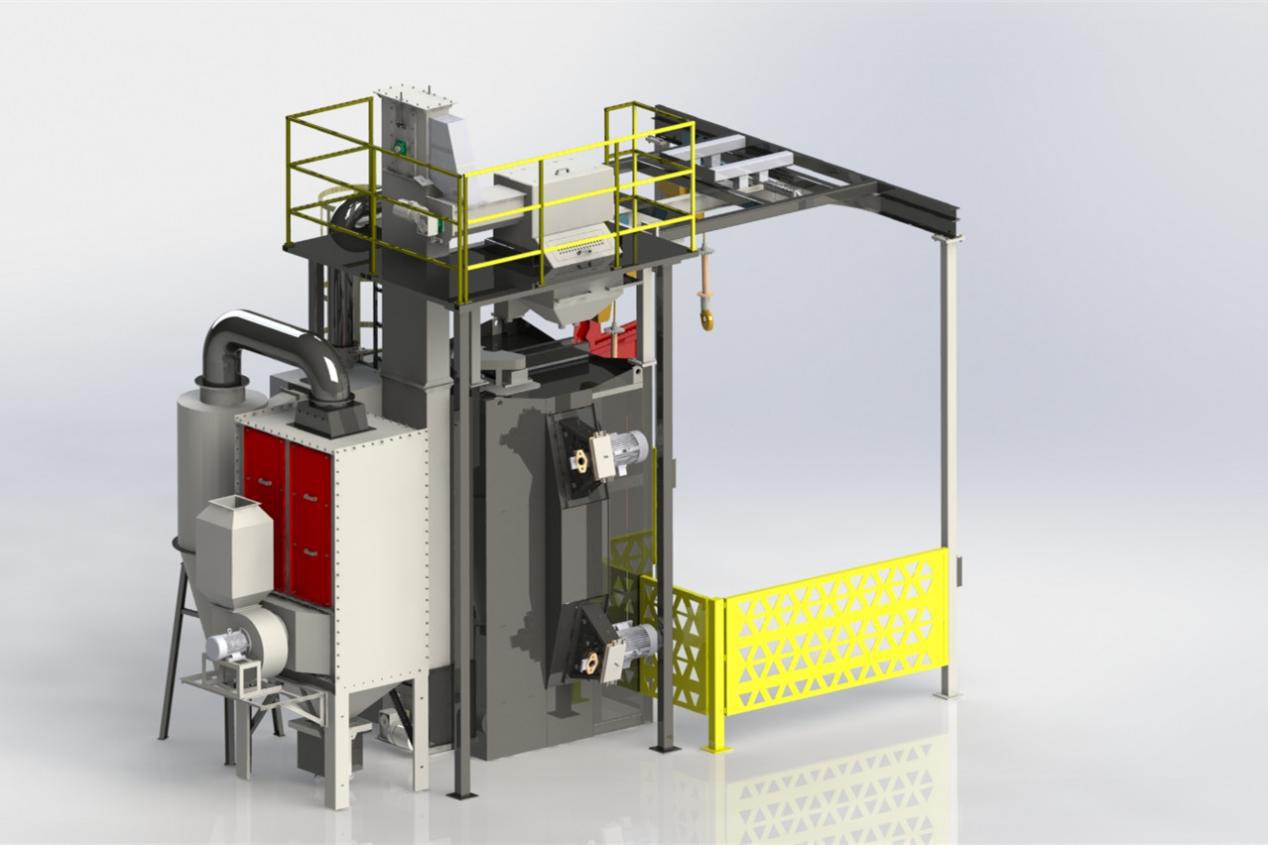

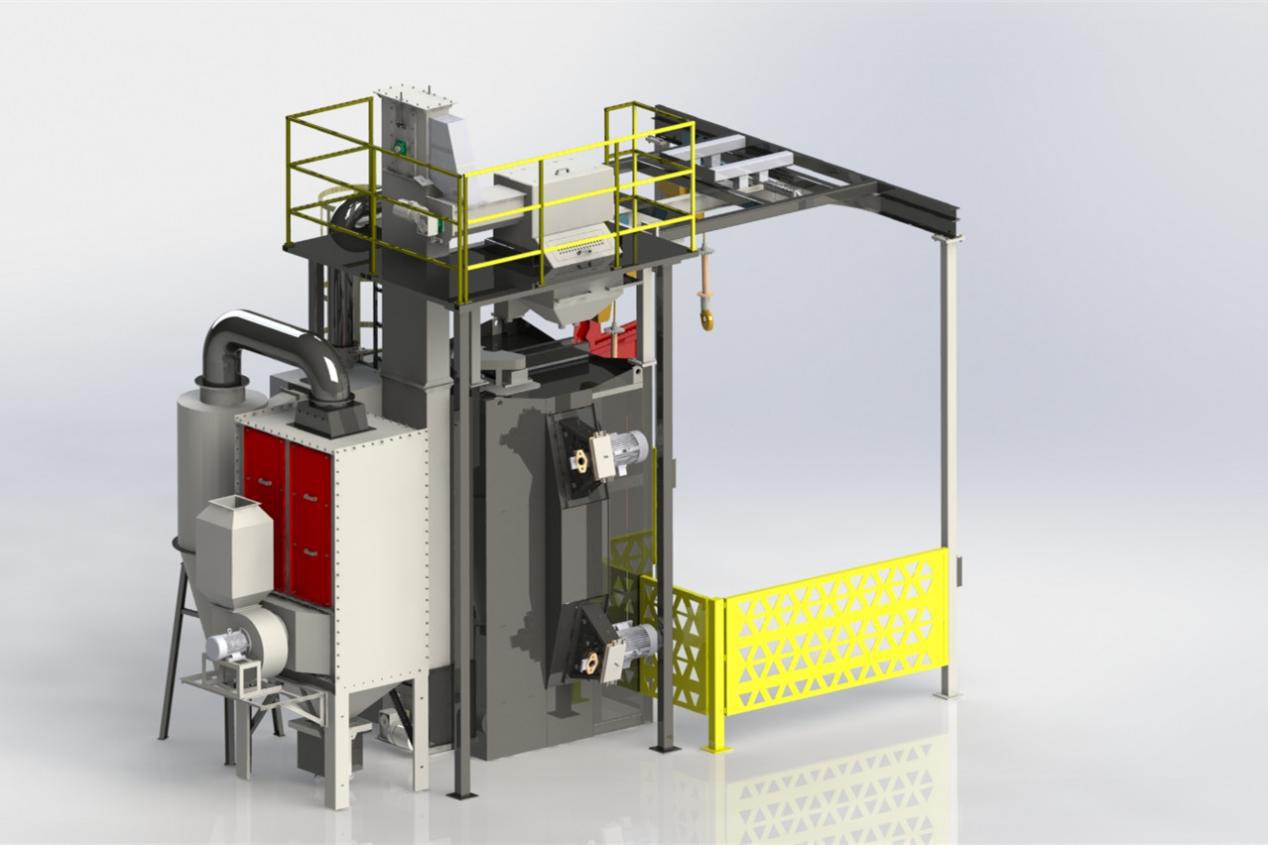

A checklist of what should be noticed in shot blaster installation

1. Every time the assembly of a part of the shot blasting machine is completed, the following items must be checked. If the assembly problem is found, it should be analyzed and processed in time.

(1) Check the integrity of the assembly work, the assembly drawings, and make sure there is no missing part.

(2) Accuracy of the installation positions of the blasting machine guard, screws, impeller, etc., according to the assembly drawings or the requirements described in the above specifications.

(3) The reliability of the fixed part of the connecting sleeve, ensure that the fastening screws meet the torque required for assembly, and the special fasteners meet the requirements for preventing looseness.

2. After the final assembly of the blasting machine is completed, the connection between the assembly parts is checked, and the inspection contents are measured according to the prescribed assembly standard for casting equipment.

3. After the final assembly of the shot blasting machine, the iron filings, debris, dust, etc. of all parts of the machine should be cleaned to ensure that there are no obstacles in each transmission part.

4. When the shot blasting machine is tested, carefully monitor the starting process. After the machine starts, observe the main ammeter parameters at once and check if the moving parts are moving normally.

5. The main working parameters include the speed of the blasting machine motor, the smoothness of the motion, the rotation of each drive shaft, as well as temperature, vibration and noise.

(1) Check the integrity of the assembly work, the assembly drawings, and make sure there is no missing part.

(2) Accuracy of the installation positions of the blasting machine guard, screws, impeller, etc., according to the assembly drawings or the requirements described in the above specifications.

(3) The reliability of the fixed part of the connecting sleeve, ensure that the fastening screws meet the torque required for assembly, and the special fasteners meet the requirements for preventing looseness.

2. After the final assembly of the blasting machine is completed, the connection between the assembly parts is checked, and the inspection contents are measured according to the prescribed assembly standard for casting equipment.

3. After the final assembly of the shot blasting machine, the iron filings, debris, dust, etc. of all parts of the machine should be cleaned to ensure that there are no obstacles in each transmission part.

4. When the shot blasting machine is tested, carefully monitor the starting process. After the machine starts, observe the main ammeter parameters at once and check if the moving parts are moving normally.

5. The main working parameters include the speed of the blasting machine motor, the smoothness of the motion, the rotation of each drive shaft, as well as temperature, vibration and noise.